Impulse sealing bars and shaped dies

Examples of standard executions

Examples of the standard model:

Further information you will find here.

General technical information

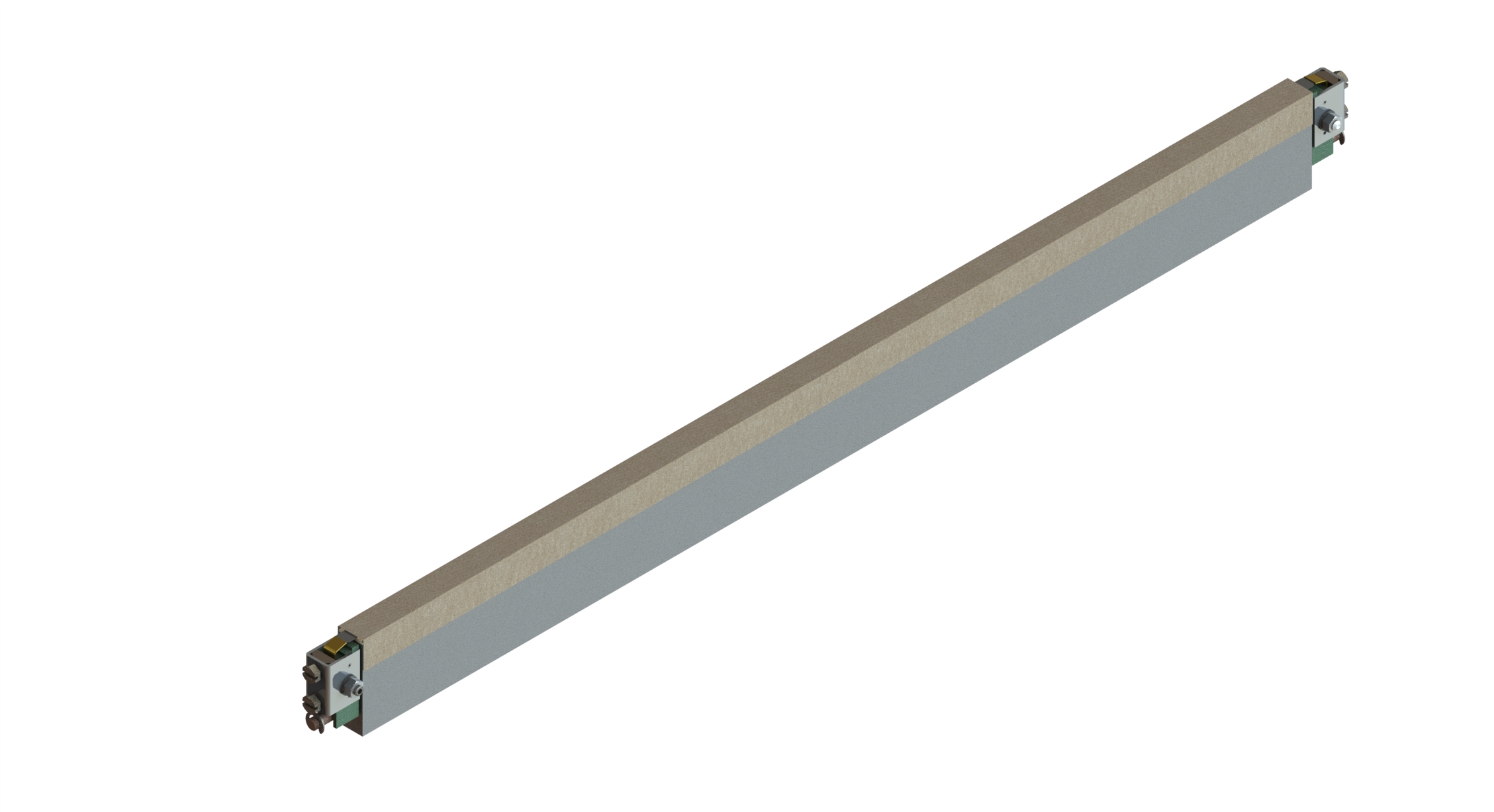

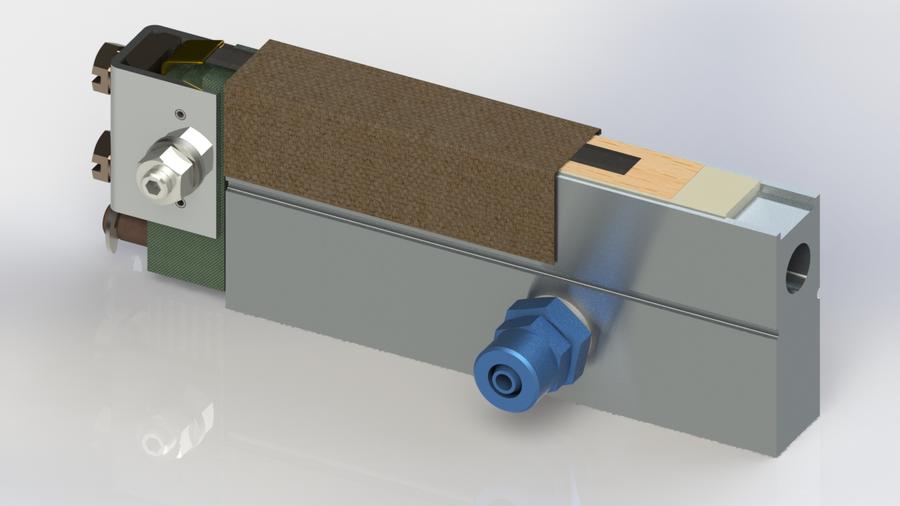

Straight impulse bars

Compensators / tensioners for impulse bars take thermal elongation, mechanical tolerances and for electrical contact of the heating element. Our designs use linear motion only, since it ensures maximum service life of the seal element. Choice of design depends e.g. on bar length and seal wire cross section.

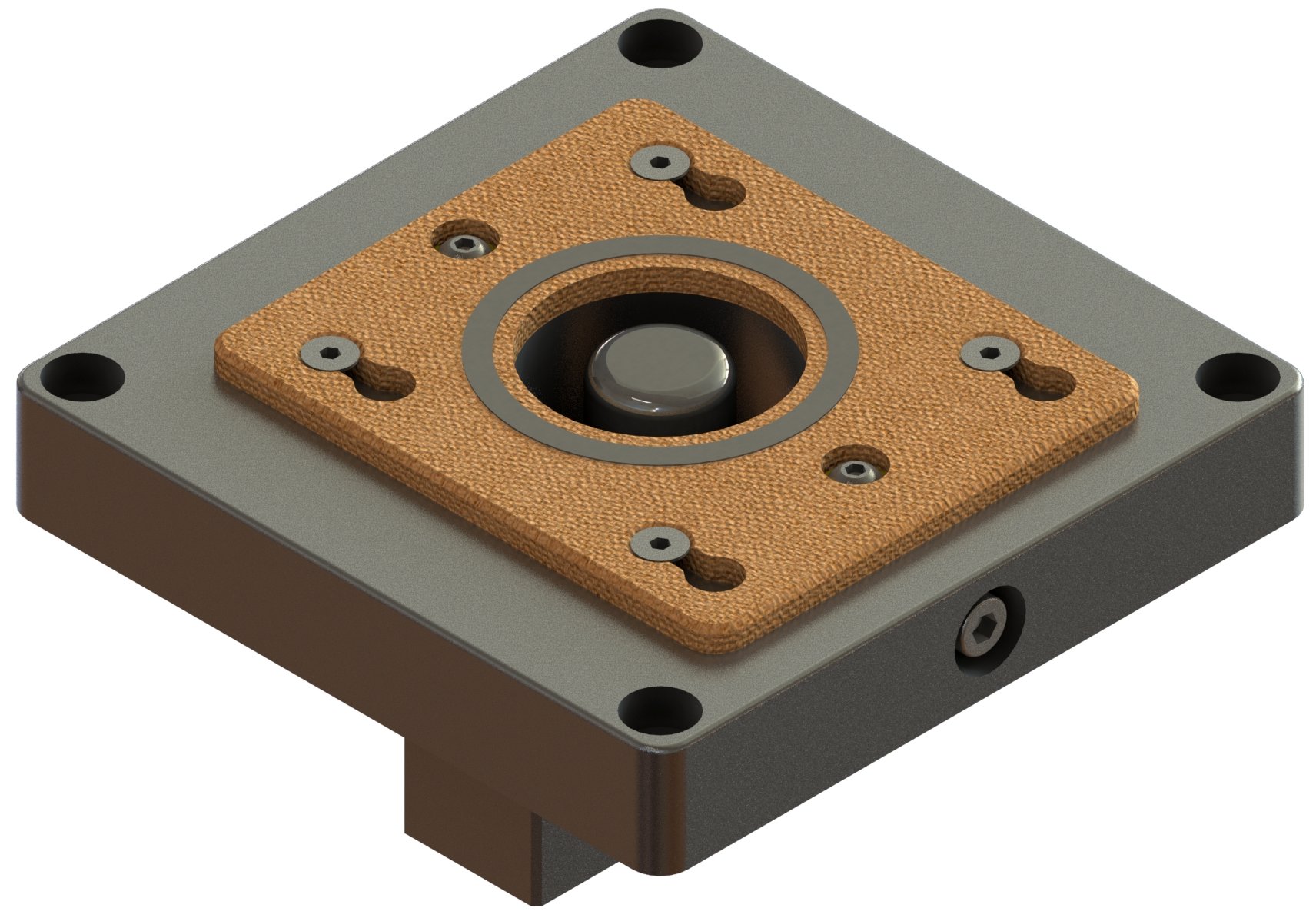

Ring-heating modules

The application is heat-sealing ports into film bags, which are e.g. in use for pharmaceutical applications. They generate a ring-shaped active zone, which is adjusted to the port flange. In comparison to conventional ring sealing bands, electric terminals remain invisible in the seam. Replacement is possible within a minute, reducing downtime considerably. There are no protruding parts in the seal level.

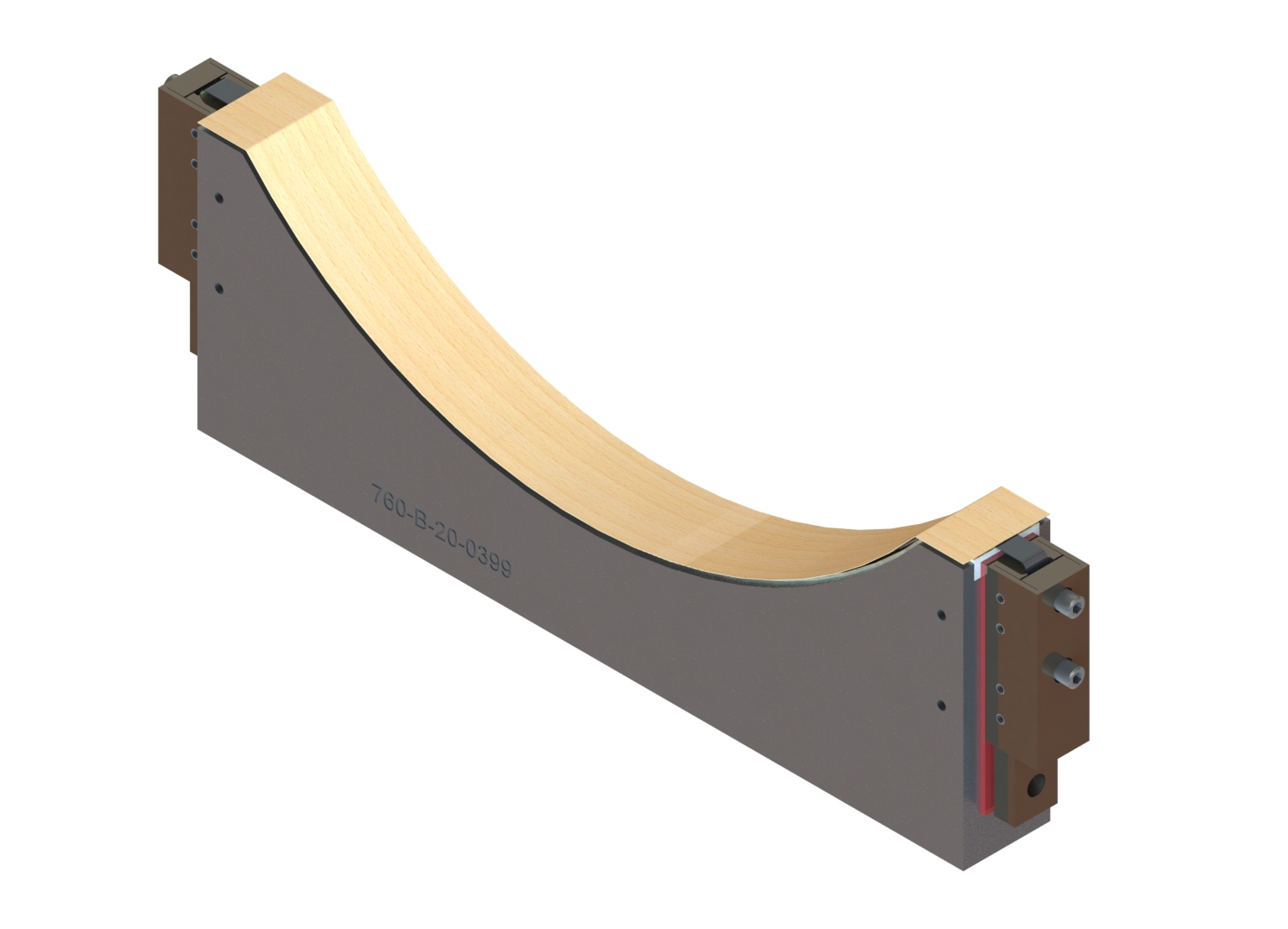

Contoured impulse bars

For heat-sealing cylindrical ports, such dies are in use. Depending on the diameter, either two or four bars are required. Contoured bars are closed as a pair, making necessary two consecutive heat-sealing cycles with four bars.