Glossary

Many technical terms are used in connection with forming shoulders that not every packaging machine operator is familiar with. Below is a list of the most important terms with brief explanations:

Bag width

The bag width or (flat) bag width is the width of the flattened tube, measured across the processing direction.

Film width

The film width is the width of the flat film from which the tubular bag is made. This corresponds to the width (or height) of the film roll used. It must also take into account the width for seam formation.

Inlet angle

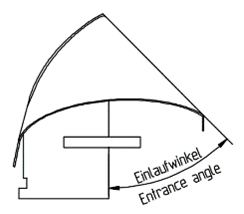

The inlet angle is one of the most important dimensions of a forming shoulder. There are various definitions of this angle in the industry, which can lead to confusion. Our definition is as follows:

The inlet angle describes the angle between the rear inlet surface of the corrugated plate of the forming shoulder (i.e. where the film enters) and the vertical plane that lies in the product flow or the imaginary axis of the filling tube. This angle can have either an acute or blunt character, which has a significant influence on the geometry of the forming shoulder.

Longitudinal seam

The longitudinal seam is the weld seam that connects the two edges of the film together and thus forms a closed tube. This runs in the processing direction of the packaging process. The design of this seam is determined by the bag design or the longitudinal welding device of the packaging machine.

Fin seam

With a fin seam (or fold-over seam), the insides of the two edges of the tubular bag are welded together. This creates a so-called "fin". This can either be folded to the left or right on the tubular bag or protrude vertically from the tubular bag.

Overlapping seam

With an overlap seam, the inside of one edge is welded to the outside of the other. There are two ways of doing this:

Either the right edge is guided over the left edge so that the inside of the right edge is welded to the outside of the left edge in an overlapping manner ("right over left").

Or the left side is placed over the right side so that the left inner side is welded to the right outer wall in an overlapping manner (“left over right”).

Form shoulder

Form shoulders are three-dimensional shaped bodies that form a tube from a flat film strip. These can have a round, rectangular or other polygonal cross-section.

Format set

The format set is the higher-level assembly in which the form shoulder is installed. Essentially, a format set always consists of a forming shoulder, filling tube and holding parts (traverses, columns, handles, etc.). Depending on the requirements and intended use, the format set can contain other components.

Filling tube

This refers to a tubular component around whose outer surface the tubular bag is formed. The product to be packaged (filling material) is transported into the tubular bag through the inner opening. In vertical tubular bag machines, this is usually done by gravity.

Valve channel

For certain types of packaging (e.g. for coffee), a plastic valve is attached to the inside of the bag. It is pulled over the forming shoulder together with the film when the tube is formed. For the valve, the filling tube and the forming shoulder must contain corresponding recesses that form a channel.

Funnel

The funnel usually serves as an interface between the format set and the filling unit above it, which is responsible for feeding and portioning the filling material. The funnel can have different cross-sections and its dimensions must match the machine and the format set.

A special form is the so-called snack funnel. Due to their special shape, these have a slightly larger cross-section than normal funnels, as they have a diagonally cut passage at the lower end (conical cut). This can increase the throughput during packaging.

Edge forming

With block bottom bags, it is possible to reshape the resulting long edges of the bag in order to make the shape more precise ("cold edge forming"). This is achieved by small adjustable folding elements that are attached below the forming shoulder.

Extraction

When packaging powdery or porous products, dust or particles can arise that are undesirable in the tubular bag or for the seam formation. To avoid this, a suction device can be provided. It reduces such residues from the filling area.

The filling pipe is designed with a nozzle for connecting a suction unit. If the suction process is to take place at a specific position in the tube, the filling tube can be designed with an integrated channel.

Inner tube

The inner tube is a thin-walled tube that has a smaller cross-section than the filling tube. It is positioned in the middle of the filling tube and separates the area for the filling material to be packaged from other components that are also located inside the filling tube (e.g. suction channels or gassing tubes). It can also be used if hygiene regulations require it, as sound insulation, or to "drop" the filling material more precisely as it falls through the format set.

Gassing

The packaging of certain products (e.g. coffee) requires a protective gas atmosphere. For this purpose, small tubes are provided in the filling tube through which the protective gas is introduced, returned ("flushed") and monitored by measuring probes.

Spreader

After leaving the filling tube, the film tube is no longer supported. In order to be able to carry out the cross-welding of flat bags with as few creases as possible, a spreading device is provided at the lower end of the filling tube, just above the cross-welding jaws.

One design variant consists of two to four wires ("round spreaders"). Another contains two elongated sheet metal parts ("flat spreaders"), which are positioned laterally under the pull-off and point slightly outwards. The bag is thus stretched from the inside and thus converted from the previously cylindrical shape into the finished flat cross-section.

Chute

The component which is additionally attached to the lower end of the filling tube is called a chute or mouthpiece. It gives the film tube its final cross-sectional shape. For example, a rectangular block-bottom bag can be produced using a format set with a round filling tube and forming shoulder cross-section.

QuadSeal

A QuadSeal or "bag with edge welding" is a special form of tubular bag in which each long edge is provided with a weld seam. One of these weld seams can also form the closing seam at the same time. The edge seals stabilize the shape of the finished bag and give it an attractive appearance, as is desired for consumer packaging.

Doypack

A Doypack or Ropack is a tubular bag with an oval or elliptical cross-section and base.

Calibration ring

Every component has dimensional tolerances, and this also applies to a forming shoulder. The tubular bags produced in this way are therefore subject to a variation in their cross-section. To improve dimensional accuracy, a calibration device can be attached under the forming shoulder. It consists of a slotted plastic ring with an adjusting screw. It allows the unwelded film tube cross-section to be precisely adjusted before entering the longitudinal welding device underneath.