The change in the web path is carried out using a splice connection to save time. To do this, the end of the empty roll and the beginning of the new one must be cut cleanly and connected with adhesive tape.

Many v/f/f/s-machines do not have a corresponding device.

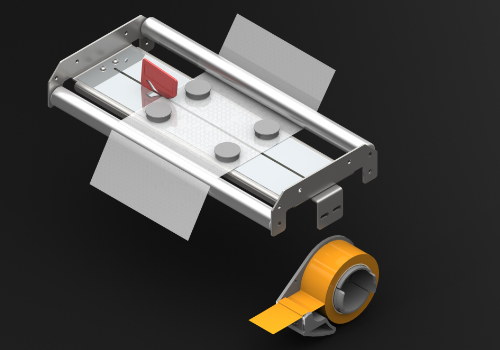

We offer a universal splicing-device for retrofitting and also for new designs. It has deflection rollers for installation typically between film roll and dancer roller system. The overlapping film webs can be cut and spliced exactly butt-to-butt.

Our splice modules are available in many standard widths and include an adhesive tape unwinder for attachment to the machine.